IoT in Logistics & Supply Chain: Benefits & Use Cases

5 min read

5 min read

Logistics has always experienced challenges like inventory management, route optimization, and shipment tracking. These problems give rise to inefficiencies and increase the cost and time of doing business, thus affecting both the business and the consumer.

However, with the advent of IoT, these traditional challenges have been addressed in a novel way. IoT devices ensure real-time monitoring of goods and other processes and also assist in making the right decisions. This technology also increases overall capacity, decreases costs, and improves customer satisfaction.

Additionally, IoT mobile app development services have become instrumental in streamlining logistics operations by providing real-time tracking and seamless communication between various stakeholders.

Here in this blog, we will give an insight concerning how IoT solutions are being applied in the logistics sector, accompanied by statistics. For example, IoT adoption in logistics is expected to reduce operational costs by 25% by 2025.

IoT logistics refers to connecting and applying devices and sensors in logistics. These are the sensors, the devices, the connectivity, and the analytics. Sensors monitor measurable parameters such as temperature or position.

Meanwhile, RFID tags and GPS devices offer information in real time. Connectivity facilitates the communication process, and data analysis turns this information into usefulness. Internet of Things technology for logistics includes Smart sensors, GPS trackers, and RFID tags for tracking and stock control.

The Internet of Things IoT in the logistics market is progressing briskly, with the market forecast to reach $63.7 billion in 2026 with a compound annual growth rate (CAGR) of 12.4%.

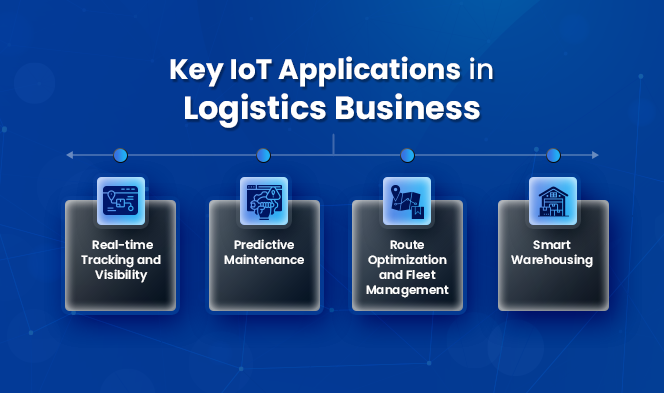

1. Real-time Tracking and Visibility:

In today’s business world, IoT technology makes monitoring the location of shipments, vehicles, and cargo easier. This technology allows GPS-enabled devices and sensors to track the position of the goods in the supply chain in real time.

Well-known corporations such as DHL are using IoT to track consignments worldwide and make them more transparent to customers. This real-time data enables a company to address delay issues, modify routes, and thus offer exact delivery times.

2. Predictive Maintenance:

IoT is already reshaping how logistics companies manage their assets, whether vehicles, trucks, forklifts, etc. Therefore, through the IoT sensors, the companies can see the condition of different machinery and prevent them from developing faults that would cause the machines to break down.

Reliability maintenance enables failure anticipation, thereby reducing losses through a machine breakdown. This approach decreases repair expenses and guarantees that equipment is optimum, ensuring smooth operations.

3. Smart Warehousing:

Internet of Things sensors and automation are changing the face of inventory and stocking items in warehouses. These sensors follow the movement of products in real-time, making the inventory accurate and minimizing human intervention.

The IoT empowers order-making and warehouse management automation systems by quickening order delivery rates. It also provides a competitive advantage by meeting customers’ needs more promptly.

4. Route Optimization and Fleet Management:

IoT devices collect a lot of information about traffic flow, weather, or road conditions that can be considered to improve delivery routes. This data can also help logistics companies by changing the route to reduce the time wasted and fuel used.

By getting it right at this level, companies will be able to cut their bills and reduce the duration between when the goods are shipped and delivered to the intended destination. This helps to increase fleet management and improve customer satisfaction

IoT technology comes in handy for the overall visibility of the supply chain through IoT connections of devices and sensors that look into the goods in transit. Such systems are based on IoT technology and provide real-time location and status of the items.

For delicate products, such as temperature-sensitive products, IoT security systems ensure the products’ state is constantly checked with respect to the environment. If the environment conditions change, an alarm is sounded.

For instance, where there are risks such as cargo theft, IoT devices can notify the concerned parties. This monitoring assists in identifying disruptive changes or irregularities so that losses can be prevented effectively.

IoT applications are also evolving how customer experience is to be differentiated by enabling real time updates on shipment status. Using connected devices, customers can get the status of their orders right from the time when it is dispatched through delivery.

This means delivery estimates are better fulfilled, and little time is spent on miscommunications or changes in the supply’s status. The various customer encounters are agile through automated notification of expected arrival times.

The same applies to removing risks, as predictive analytics also means avoiding problems that may hinder efficient delivery.

IoT effectively reduces fuel usage since vehicle performance is continually monitored, and driving behaviors are also observed in real time. This data makes it possible for fleet managers to pinpoint and alter bad driving habits, thus cutting fuel expenses.

The application of Automation in warehouses and transport means less labor usage as most of the work gets mechanized. The usage of IoT also makes the work of sorting, packaging, and delivering more efficient and accurate.

Further, IoT is highly vital in handling inventory management to track and order inventory as needed, due to which there is no overstocking and occurrence of stockouts.

1. Data Privacy and Security:

For the logistics industry, IoT devices gather data in large volumes and mainly of a sensitive nature hence data privacy and security become paramount. This data is normally sent over networks, a common target for cyber criminals.

Hackers may exploit these vulnerabilities, resulting in data loss or theft. On these issues, it is imperative that logistics companies should employ strong encryption measures to counter such threats and should redesign their security measures progressively to counter novel threats.

2. Integration with Legacy Systems:

A large number of logistics companies are still employing outdated systems that do not integrate well with IoT systems. Integrating IoT with existing solutions means addressing numerous challenges that may require time, skills, and money.

Another significant issue is the lack of compatibility between various kinds of IoT devices. One way to address this problem is to implement middleware that mediates between IoT devices and preexisting systems.

3. High Initial Investment:

The initial investment in IoT logistics is usually relatively high due to the costs of the physical devices, as well as the necessary software and setup costs. When it comes to small logistic companies, these costs may make a deep impact and may act as a constraint for the new entry.

However, the long-term return on investment (ROI) is quite great because organizations can enhance efficiency, minimize operations costs, and improve customer satisfaction. Organizations seeking to implement green supply chain management strategies can overcome this by starting with some pilot projects and gradually expanding the results.

4. Data Overload and Analysis:

Many IoT devices are used in logs to transport data to companies, and often this data is very huge, which could be a problem if not handled appropriately. Thus, such data aggregates can’t be analyzed with simple tools and require highly specialized knowledge to extract useful information from collected points.

When these systems are not appropriately implemented, then crucial optimization may go unnoticed. To address this challenge, logistics companies must embrace upgraded data analytics systems to decipher data in real-time flows and enable the companies to make the right decisions.

In conclusion, IoT transforms logistics by improving its performance, providing real-time monitoring, and lowering expenses. Hence, optimization of product flow, inventory monitoring, and control of maintenance requirements are some of the benefits that logistics companies will accrue from connected devices.

As businesses look to develop an IoT app, cognition is an inevitable trend in the logistics industry, and IoT is bound to become even more important as an enabler of new technologies and better decisions. Talking about the future of logistics, one cannot ignore IoT solutions, and companies need to prepare for their changes.

Get in touch with us now to learn how our specialists can assist you in improving your logistics through the use of IoT.

Logistics has always experienced challenges like inventory management, route optimization, and shipment tracking. These problems give rise to inefficiencies and increase the cost and time of doing business, thus affecting both the business and the consumer.

However, with the advent of IoT, these traditional challenges have been addressed in a novel way. IoT devices ensure real-time monitoring of goods and other processes and also assist in making the right decisions. This technology also increases overall capacity, decreases costs, and improves customer satisfaction.

Additionally, IoT mobile app development services have become instrumental in streamlining logistics operations by providing real-time tracking and seamless communication between various stakeholders.

Here in this blog, we will give an insight concerning how IoT solutions are being applied in the logistics sector, accompanied by statistics. For example, IoT adoption in logistics is expected to reduce operational costs by 25% by 2025.

IoT logistics refers to connecting and applying devices and sensors in logistics. These are the sensors, the devices, the connectivity, and the analytics. Sensors monitor measurable parameters such as temperature or position.

Meanwhile, RFID tags and GPS devices offer information in real time. Connectivity facilitates the communication process, and data analysis turns this information into usefulness. Internet of Things technology for logistics includes Smart sensors, GPS trackers, and RFID tags for tracking and stock control.

The Internet of Things IoT in the logistics market is progressing briskly, with the market forecast to reach $63.7 billion in 2026 with a compound annual growth rate (CAGR) of 12.4%.

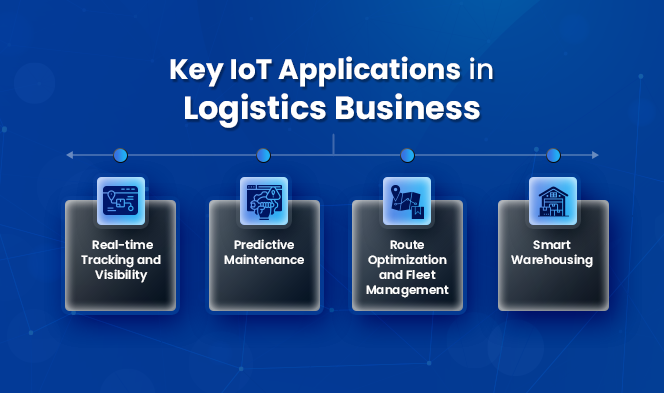

1. Real-time Tracking and Visibility:

In today’s business world, IoT technology makes monitoring the location of shipments, vehicles, and cargo easier. This technology allows GPS-enabled devices and sensors to track the position of the goods in the supply chain in real time.

Well-known corporations such as DHL are using IoT to track consignments worldwide and make them more transparent to customers. This real-time data enables a company to address delay issues, modify routes, and thus offer exact delivery times.

2. Predictive Maintenance:

IoT is already reshaping how logistics companies manage their assets, whether vehicles, trucks, forklifts, etc. Therefore, through the IoT sensors, the companies can see the condition of different machinery and prevent them from developing faults that would cause the machines to break down.

Reliability maintenance enables failure anticipation, thereby reducing losses through a machine breakdown. This approach decreases repair expenses and guarantees that equipment is optimum, ensuring smooth operations.

3. Smart Warehousing:

Internet of Things sensors and automation are changing the face of inventory and stocking items in warehouses. These sensors follow the movement of products in real-time, making the inventory accurate and minimizing human intervention.

The IoT empowers order-making and warehouse management automation systems by quickening order delivery rates. It also provides a competitive advantage by meeting customers’ needs more promptly.

4. Route Optimization and Fleet Management:

IoT devices collect a lot of information about traffic flow, weather, or road conditions that can be considered to improve delivery routes. This data can also help logistics companies by changing the route to reduce the time wasted and fuel used.

By getting it right at this level, companies will be able to cut their bills and reduce the duration between when the goods are shipped and delivered to the intended destination. This helps to increase fleet management and improve customer satisfaction

IoT technology comes in handy for the overall visibility of the supply chain through IoT connections of devices and sensors that look into the goods in transit. Such systems are based on IoT technology and provide real-time location and status of the items.

For delicate products, such as temperature-sensitive products, IoT security systems ensure the products’ state is constantly checked with respect to the environment. If the environment conditions change, an alarm is sounded.

For instance, where there are risks such as cargo theft, IoT devices can notify the concerned parties. This monitoring assists in identifying disruptive changes or irregularities so that losses can be prevented effectively.

IoT applications are also evolving how customer experience is to be differentiated by enabling real time updates on shipment status. Using connected devices, customers can get the status of their orders right from the time when it is dispatched through delivery.

This means delivery estimates are better fulfilled, and little time is spent on miscommunications or changes in the supply’s status. The various customer encounters are agile through automated notification of expected arrival times.

The same applies to removing risks, as predictive analytics also means avoiding problems that may hinder efficient delivery.

IoT effectively reduces fuel usage since vehicle performance is continually monitored, and driving behaviors are also observed in real time. This data makes it possible for fleet managers to pinpoint and alter bad driving habits, thus cutting fuel expenses.

The application of Automation in warehouses and transport means less labor usage as most of the work gets mechanized. The usage of IoT also makes the work of sorting, packaging, and delivering more efficient and accurate.

Further, IoT is highly vital in handling inventory management to track and order inventory as needed, due to which there is no overstocking and occurrence of stockouts.

1. Data Privacy and Security:

For the logistics industry, IoT devices gather data in large volumes and mainly of a sensitive nature hence data privacy and security become paramount. This data is normally sent over networks, a common target for cyber criminals.

Hackers may exploit these vulnerabilities, resulting in data loss or theft. On these issues, it is imperative that logistics companies should employ strong encryption measures to counter such threats and should redesign their security measures progressively to counter novel threats.

2. Integration with Legacy Systems:

A large number of logistics companies are still employing outdated systems that do not integrate well with IoT systems. Integrating IoT with existing solutions means addressing numerous challenges that may require time, skills, and money.

Another significant issue is the lack of compatibility between various kinds of IoT devices. One way to address this problem is to implement middleware that mediates between IoT devices and preexisting systems.

3. High Initial Investment:

The initial investment in IoT logistics is usually relatively high due to the costs of the physical devices, as well as the necessary software and setup costs. When it comes to small logistic companies, these costs may make a deep impact and may act as a constraint for the new entry.

However, the long-term return on investment (ROI) is quite great because organizations can enhance efficiency, minimize operations costs, and improve customer satisfaction. Organizations seeking to implement green supply chain management strategies can overcome this by starting with some pilot projects and gradually expanding the results.

4. Data Overload and Analysis:

Many IoT devices are used in logs to transport data to companies, and often this data is very huge, which could be a problem if not handled appropriately. Thus, such data aggregates can’t be analyzed with simple tools and require highly specialized knowledge to extract useful information from collected points.

When these systems are not appropriately implemented, then crucial optimization may go unnoticed. To address this challenge, logistics companies must embrace upgraded data analytics systems to decipher data in real-time flows and enable the companies to make the right decisions.

In conclusion, IoT transforms logistics by improving its performance, providing real-time monitoring, and lowering expenses. Hence, optimization of product flow, inventory monitoring, and control of maintenance requirements are some of the benefits that logistics companies will accrue from connected devices.

As businesses look to develop an IoT app, cognition is an inevitable trend in the logistics industry, and IoT is bound to become even more important as an enabler of new technologies and better decisions. Talking about the future of logistics, one cannot ignore IoT solutions, and companies need to prepare for their changes.

Get in touch with us now to learn how our specialists can assist you in improving your logistics through the use of IoT.

Logistics has always experienced challenges like inventory management, route optimization, and shipment tracking. These problems give rise to inefficiencies and increase the cost and time of doing business, thus affecting both the business and the consumer.

However, with the advent of IoT, these traditional challenges have been addressed in a novel way. IoT devices ensure real-time monitoring of goods and other processes and also assist in making the right decisions. This technology also increases overall capacity, decreases costs, and improves customer satisfaction.

Additionally, IoT mobile app development services have become instrumental in streamlining logistics operations by providing real-time tracking and seamless communication between various stakeholders.

Here in this blog, we will give an insight concerning how IoT solutions are being applied in the logistics sector, accompanied by statistics. For example, IoT adoption in logistics is expected to reduce operational costs by 25% by 2025.

IoT logistics refers to connecting and applying devices and sensors in logistics. These are the sensors, the devices, the connectivity, and the analytics. Sensors monitor measurable parameters such as temperature or position.

Meanwhile, RFID tags and GPS devices offer information in real time. Connectivity facilitates the communication process, and data analysis turns this information into usefulness. Internet of Things technology for logistics includes Smart sensors, GPS trackers, and RFID tags for tracking and stock control.

The Internet of Things IoT in the logistics market is progressing briskly, with the market forecast to reach $63.7 billion in 2026 with a compound annual growth rate (CAGR) of 12.4%.

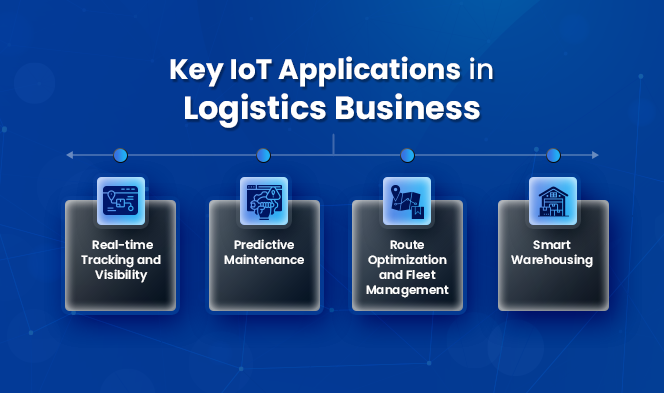

1. Real-time Tracking and Visibility:

In today’s business world, IoT technology makes monitoring the location of shipments, vehicles, and cargo easier. This technology allows GPS-enabled devices and sensors to track the position of the goods in the supply chain in real time.

Well-known corporations such as DHL are using IoT to track consignments worldwide and make them more transparent to customers. This real-time data enables a company to address delay issues, modify routes, and thus offer exact delivery times.

2. Predictive Maintenance:

IoT is already reshaping how logistics companies manage their assets, whether vehicles, trucks, forklifts, etc. Therefore, through the IoT sensors, the companies can see the condition of different machinery and prevent them from developing faults that would cause the machines to break down.

Reliability maintenance enables failure anticipation, thereby reducing losses through a machine breakdown. This approach decreases repair expenses and guarantees that equipment is optimum, ensuring smooth operations.

3. Smart Warehousing:

Internet of Things sensors and automation are changing the face of inventory and stocking items in warehouses. These sensors follow the movement of products in real-time, making the inventory accurate and minimizing human intervention.

The IoT empowers order-making and warehouse management automation systems by quickening order delivery rates. It also provides a competitive advantage by meeting customers’ needs more promptly.

4. Route Optimization and Fleet Management:

IoT devices collect a lot of information about traffic flow, weather, or road conditions that can be considered to improve delivery routes. This data can also help logistics companies by changing the route to reduce the time wasted and fuel used.

By getting it right at this level, companies will be able to cut their bills and reduce the duration between when the goods are shipped and delivered to the intended destination. This helps to increase fleet management and improve customer satisfaction

IoT technology comes in handy for the overall visibility of the supply chain through IoT connections of devices and sensors that look into the goods in transit. Such systems are based on IoT technology and provide real-time location and status of the items.

For delicate products, such as temperature-sensitive products, IoT security systems ensure the products’ state is constantly checked with respect to the environment. If the environment conditions change, an alarm is sounded.

For instance, where there are risks such as cargo theft, IoT devices can notify the concerned parties. This monitoring assists in identifying disruptive changes or irregularities so that losses can be prevented effectively.

IoT applications are also evolving how customer experience is to be differentiated by enabling real time updates on shipment status. Using connected devices, customers can get the status of their orders right from the time when it is dispatched through delivery.

This means delivery estimates are better fulfilled, and little time is spent on miscommunications or changes in the supply’s status. The various customer encounters are agile through automated notification of expected arrival times.

The same applies to removing risks, as predictive analytics also means avoiding problems that may hinder efficient delivery.

IoT effectively reduces fuel usage since vehicle performance is continually monitored, and driving behaviors are also observed in real time. This data makes it possible for fleet managers to pinpoint and alter bad driving habits, thus cutting fuel expenses.

The application of Automation in warehouses and transport means less labor usage as most of the work gets mechanized. The usage of IoT also makes the work of sorting, packaging, and delivering more efficient and accurate.

Further, IoT is highly vital in handling inventory management to track and order inventory as needed, due to which there is no overstocking and occurrence of stockouts.

1. Data Privacy and Security:

For the logistics industry, IoT devices gather data in large volumes and mainly of a sensitive nature hence data privacy and security become paramount. This data is normally sent over networks, a common target for cyber criminals.

Hackers may exploit these vulnerabilities, resulting in data loss or theft. On these issues, it is imperative that logistics companies should employ strong encryption measures to counter such threats and should redesign their security measures progressively to counter novel threats.

2. Integration with Legacy Systems:

A large number of logistics companies are still employing outdated systems that do not integrate well with IoT systems. Integrating IoT with existing solutions means addressing numerous challenges that may require time, skills, and money.

Another significant issue is the lack of compatibility between various kinds of IoT devices. One way to address this problem is to implement middleware that mediates between IoT devices and preexisting systems.

3. High Initial Investment:

The initial investment in IoT logistics is usually relatively high due to the costs of the physical devices, as well as the necessary software and setup costs. When it comes to small logistic companies, these costs may make a deep impact and may act as a constraint for the new entry.

However, the long-term return on investment (ROI) is quite great because organizations can enhance efficiency, minimize operations costs, and improve customer satisfaction. Organizations seeking to implement green supply chain management strategies can overcome this by starting with some pilot projects and gradually expanding the results.

4. Data Overload and Analysis:

Many IoT devices are used in logs to transport data to companies, and often this data is very huge, which could be a problem if not handled appropriately. Thus, such data aggregates can’t be analyzed with simple tools and require highly specialized knowledge to extract useful information from collected points.

When these systems are not appropriately implemented, then crucial optimization may go unnoticed. To address this challenge, logistics companies must embrace upgraded data analytics systems to decipher data in real-time flows and enable the companies to make the right decisions.

In conclusion, IoT transforms logistics by improving its performance, providing real-time monitoring, and lowering expenses. Hence, optimization of product flow, inventory monitoring, and control of maintenance requirements are some of the benefits that logistics companies will accrue from connected devices.

As businesses look to develop an IoT app, cognition is an inevitable trend in the logistics industry, and IoT is bound to become even more important as an enabler of new technologies and better decisions. Talking about the future of logistics, one cannot ignore IoT solutions, and companies need to prepare for their changes.

Get in touch with us now to learn how our specialists can assist you in improving your logistics through the use of IoT.

Odoo

54

By Uttam Jain

Artificial Intelligence (AI)

148

By Nandeep Barochiya

Odoo

101

By Uttam Jain