7101

Why IoT is the Key to Modernizing Your Warehouse Operations?

08 Oct, 2020

10 min read

7101

08 Oct, 2020

10 min read

Table of content

There have been countless issues in warehouses, slow-moving processes, errors, and lack of timely information, which affects the decision-making process and thus slows down operations.

These issues can lead to increased expenses, time wastage, and unsatisfied organizational clients or customers. The IoT is slowly revolutionizing warehouse management due to the digital interconnectivity of devices, assets, and people.

Technologies IoT assists the warehouses by tracking the status of stocks and various equipment, reducing time and increasing efficiency for the given tasks. MarketedsandMarkets’ report on the IoT in the logistics market reveals that this market is projected to rise from $21.0 billion in 2020 to $75.0 billion in 2025.

With the help of IoT software development services, warehouses can now implement these technologies to optimize their businesses. In this blog, you will learn more about the role of IoT concerning warehouses and why it is essential to integrate it into your warehouse.

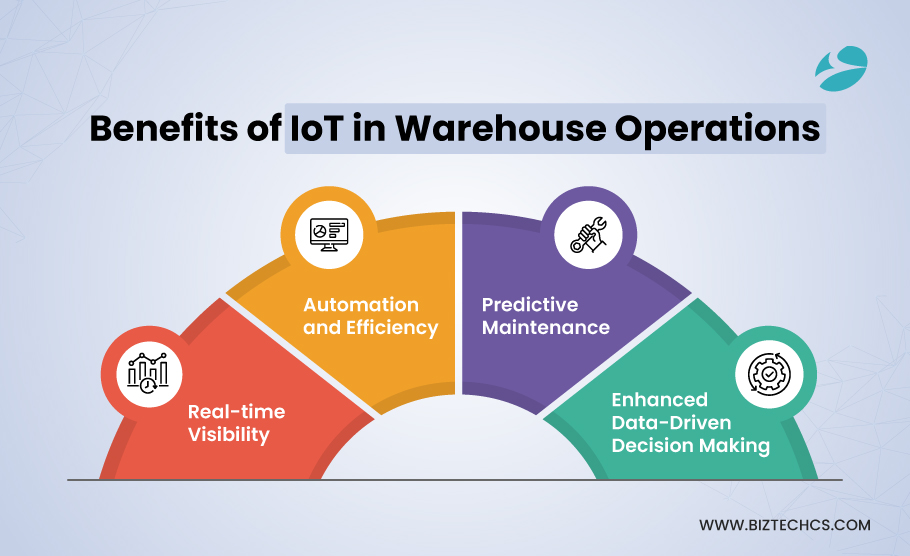

Smart sensors and RFID, when implemented, will help provide accurate location tracking of inventories, pallets, and equipment in the warehouse. The information these sensors relay enables warehouse managers to be updated on the location of items at any one time.

This visibility helps reduce the chances of misplaced stocks and thus enhances other functioning processes. It also helps in quicker decision-making and coordination between the inter-team communications, hence helping improve warehouses.

IoT is considered to have a crucial role in automation as it includes the usage of Internet-connected automobiles and drones, intelligent robots, and vehicles. These technologies can handle tasks such as picking and sorting products, delivering them, and transporting them within the premises faster and more accurately than manpower.

These devices contain IoT systems that enable self-controlling functionality and optimization according to current situations. This helps in the warehouse organization, minimizing the chances of human interference and thus leading to high performance.

The IoT sensors that can be attached to the equipment and machinery can track the equipment’s status and identify early signs of deterioration. This makes it possible for the warehouses to predict when equipment will require maintenance or repairs before a breakdown occurs.

This approach is effective in preventing the occurrence of major breakdowns, consequently minimizing on time lost and costs of repairs. Thus, the warehouses can continue their functioning uninterrupted because of the timely identification of equipment failures.

IoT data is beneficial and helps make efficient warehouse management decisions. By having accurate real-time data, the warehouse will be able to better predict the demand, manage the inventory adequately, and make the right use of available resources. Implementing a cloud WMS system further enhances this process by providing seamless, remote access to warehouse operations, ensuring better inventory tracking and workflow automation This aids in cutting waste and ensures the right product is in place when required.

Analyzing IoT data will help warehouses find meaningful and effective ways to manage work and cut expenses.

With IoT, the environment in the warehouse can be monitored in real-time. Temperature, humidity, and air quality can be monitored using sensors to check the environment for perishable goods.

For example, food products or medicine require certain temperatures for storing or they can easily get spoiled. Develop an IoT App to integrate these sensors and enable remote monitoring and control. IoT devices are capable of monitoring it and in case of any variation, it immediately alerts the owner for corrective measures to be taken.

This ensures minimization of any adverse effect on the products, such as spoilage or damage, to enhance the quality and safety of the product.

Wearable IoT devices can monitor your health and wellbeing indicators, including heart rate and body temperature among workers. They can identify symptoms of tiredness or preliminary features of diseases, such as dehydration or overheating.

When something is amiss, the signal is sent to the system’s managers or supervisors. This makes it possible to intervene on time to prevent incidents at the workplace or health complications.

Smartwatches can also sense when the wearer has fallen or met with an accident, thus alerting a caregiver for help immediately. This is much more effective than waiting for a caregiver to check up on the patient only to find out they have fallen and need help getting up.

Automation in IoT warehouses means that workers do not perform too many tasks. Sorting, inventory, and order picking are some of the activities that sensors, robots, or any other automatic systems can execute.

This reduces the need for human intervention, thus translating to an overall reduction in labor costs. In the same respect, these systems are effective and efficient in their working hence reducing overtime and staffing.

IoT systems provide real-time operational visibility, and they track products, equipment used, and shipments. By doing this, they can monitor for problems that include misplaced inventory, wrong order or even damaged goods.

For instance, with this information, the warehouse can swiftly counteract some undesirable effects and eliminate extra costs that might accrue from the deviations. This translates to reduced returns, affordable scrap prices, and minimized wastage.

The real-time data of IoT assists in increasing the operational transparency of the warehouses. Managers can monitor stocks of various materials, machines, and employees’ performance, which will help make good decisions. This data also assists in better forecasting because warehouses can be ready to meet demands when they are expected.

Through efficient resource utilization, IoT systems can also maintain optimum warehouse performance, thereby increasing system utilization and reducing the cost of operation. Latterly, the overall cost saves, which has minimized waste, labor, and errors, impacts a good return on investment.

Smart shelves connected to IoT help shelves monitor inventory in real time. These shelves can change the stock status and notify the managers when stock is low. This helps to reduce manual inventory counting and also minimize instances of possible mistakes. This means that, through effective stock management, businesses can avoid customer frustrations of waiting for their preferred brands.

Similarly, they can avoid telling their customers that the brands are out of stock. Smart shelves also create efficient capacity because of the knowledge of whichормaments are most often used by people.

Connected wearables are equipment employees wear to track their location, health conditions, and performance. These wearables transmit information to a central database in real-time, and managers can monitor workforce productivity.

They can also notify all workers about possible hazards to their health or productivity decrements. This feedback makes correcting inefficiency for an individual or the entire warehouse facility possible.

Smartwears make the workplace safer and more efficient because the workers will always work at their best.

Automated systems, such as drones and autonomous vehicles, are revolutionizing warehouse operations by handling tasks that used to be done by people. It is for auditing, barcode scanning, and checking stock that may have been misplaced.

The benefits of drone delivery are significant, as drones can quickly transport small packages within a warehouse, speeding up the process and reducing the need for human labor. Mobile robots also move items in the warehouse in an efficient manner, and besides, they minimize the involvement of people in the process.

Warehouses can work most effectively by using faster technologies in moving stocks and checking inventories.

Edge computing in warehousing is the processing of data at the point of origin or at the local level within a warehouse without going through remote servers. This technology facilitates faster decision-making as it does not require data to travel far before processing.

For instance, if a piece of machinery malfunctions, the edge devices can diagnose and correct the problem without necessarily liaising with the cloud network. This leads to faster response times, and as a result, the overall operations in the warehouse become quicker.

Edge computing ensures that warehouses remain as efficient as possible, even in areas with poor network coverage.

AI and machine learning are incorporated in IoT-enabled warehouses to forecast demand and perform several workflow analyses. IoT assists in inventory management since it gathers information about the products that AI can utilize to predict future demand for specific items to avoid over or under-stocking.

These algorithms can also be used to choose optimal pick and ship routes to ensure the process is efficient and precise. Using the information retrieved in the past, machine learning systems help in decision-making while reducing the likelihood of bottlenecks.

When integrated into the system, artificial intelligence makes the warehouses more adaptive to their surroundings and improves their performance.

Implementing IoT in warehouses entails a huge fixed cost of devices, sensors, and infrastructure. All these costs can be rather high, particularly challenging for small and medium enterprises. But in the long run, the money saved from automation, real-time monitoring, and operational measurements for predictive maintenance might fully offset the expenses.

At present times, there are still many warehouses that have implemented outdated systems and software, which makes it challenging to assimilate the new IoT technology. Integrating IoT solutions with these existing systems may sometimes take longer and be resource-intensive. This challenge can stretch the time frame for any adoption and lead to higher implementation costs.

Data generated through IoT systems can sometimes be large and may contain other operational parameters of an organization. Due to such data being transferred and stored through IoT networks, there are real threats that it may be hacked or that a cybersecurity incident will occur. The following areas are most risky: Cybersecurity and compliance with privacy standards and regulations are crucial for mitigating such risks.

In general, IoT tools should be used by staff and management, who have to be trained in their usage, and this takes a lot of time and effort, which is a significant issue. It is very common for employees to lack the ability to embrace change and/or reject new technologies that are introduced without prior support. This means that there needs to be consistent training and effective strategies to adapt the IoT systems in optimizing the operations of warehouses.

In conclusion, IoT is redefining the capabilities of warehouses by enhancing their performance, safety, and profits. Real-time tracking, automated processes, and predictive maintenance systems may help warehouses optimize their operations and minimize expenditures.

The effective collection and analysis of information from connected devices result in better decision-making and timely response to a problem.

The acceptance of IoT brings various benefits to warehouse managers who can offer a more secure and efficient service compared to the competitors. Let’s not wait any longer to start the journey of transforming the warehouse with IoT solutions.

Our solutions are based on IoT, helping to improve your warehouses and make the processes more efficient and effective. The Internet of Things developers are prepared to assist with implementing new technologies designed for your company.

Key technology trends in smart warehousing include automation, robotics, and Artificial Intelligence, significantly boosting productivity. These technologies help reduce human error and improve decision-making by capturing real-time data. By integrating these advancements, warehousing and inventory management practices are enhanced, ensuring greater efficiency and accuracy.

IoT warehouse management includes various technologies like Sensors, RFID, and GPS, combining Intelligent and connected warehouses. Real-time monitoring of inventory, equipment, and the condition of the warehouse becomes possible, which is essential for informed decision-making.

In warehouses, IoT impacts as a tool that updates assets inventory and environmental conditions. This makes the operations to be faster, frees up time, and makes the visibility in the supply chain to be better. This, as a result, leads to better decisions on the use of the resources.

Many IoT solutions that have found their place in warehouses are smart shelves, AGVs, and wearable technologies for the workers. These solutions are useful for such functions as using, picking up goods, and accomplishing assessment of the workers employed in the warehouse the safety and efficiency of the location are also enhanced.

Artificial Intelligence (AI)

5172

By Devik Gondaliya

22 Apr, 2025

Storyblok

38914

By Devik Gondaliya

02 Apr, 2025

Storyblok

39808

By Devik Gondaliya

01 Apr, 2025